|

In stock

|

Out of stock

|

||

|

|

|||

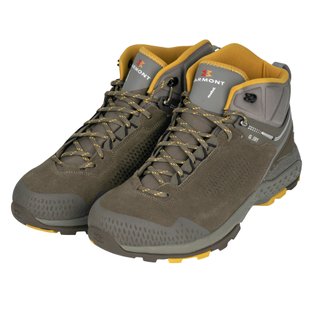

The history of the Garmont company dates back to 1867. The Italian industrialist Mr. Morlin, who develops forests and mineral deposits in northern Italy, was faced with the problem of defective shoes for workers suitable for use in the Dolomites. At the same time, the first 1.5 thousand pairs of boots with leather uppers and wooden soles were developed and manufactured. Shoes proved so well-established that they quickly became a commodity, and their production grew into a profitable and soon dominant part of the business.

In 1872, production was located in Montebeluno, where Morlin's headquarters are still located. Currently, the fifth generation of heirs own and strengthen the business, which has completely switched to the manufacture of shoes. Military orders and the production of footwear allowed the Morlin Corporation to increase production capacity and master the latest technologies.

In the 1950s, in European countries, with the growing popularity of skiing and trekking, the sweat for appropriate footwear increased dramatically. Morlin quickly jumped into the new market. In addition to shoes under the Morlin brand, since the early 60s, such well-known international brands as Nordica and Dolomite have been produced on the basis of sub-partnerships in the factories owned by the company. Since the mid-80s - Asolo and Merrell.

In 1990, Morlin introduced its Garmont brand to the market. Thanks to the experience accumulated over a period of more than an age, products under the Garmont trademark have rapidly gained recognition around the world. The new models included all the advanced developments discovered, implemented and patented by Morlin, namely:

– 1968. For the first time, a leather boot with a high rubber welt around the perimeter was produced;

– 1971 The first combined leather-synthetic upper in a trekking boot;

– 1973 Sole with air cavities;

– 1978 First plastic ski boot with rear opening (Rear Entry);

– 1995 Combined material for the production of soles and the method of production of Pebax.

and Polyurethane;

– 1997 ADD - asymmetric boot design, completely repeating the anatomical structure of the foot;

– 1998 Dual Frame Tech - sole construction that combines food and torsional rigidity with vibrating properties;

– 1999 The R2 Spine is a system that provides torsional rigidity while providing lasting softness.

In 2001 the company has crossed the threshold of 400,000 pairs of shoes for high-altitude mountaineering, lidola, rock climbing, ski-tour, trekking, hiking, walking and daily use, per year under the Garmont brand. Shoes are made in our own factories located in seven countries, but still about 80% of shoes are made in northern Italy.

pecial shoes for his workers. The decision was appropriate, considering the fact that his employees were engaged in the extraction of minerals in the mountainous regions of Northern Italy.

pecial shoes for his workers. The decision was appropriate, considering the fact that his employees were engaged in the extraction of minerals in the mountainous regions of Northern Italy.