Among the seven layers of the third generation of the army multilayer kit ECWCS, the fifth layer, consisting of a jacket and trousers, has always been the most popular among its operators. These are products with the most thoughtfulness and excellent functionality, convenient and durable.

These products are made of soft-shell fabric and are designed to be worn in cold and humid weather in addition to the sixth, membrane layer instead of field uniforms. The most commonly used jacket, which will be discussed.

Such products are used only in the army (in the Marine Corps they use their products of a similar purpose from fabrics of the same type) and are made in two colors: UCP | ACUPat and Multicam (in the licensed masking drawing Crye). Also, the jacket began to be produced in OCP.

The jacket is equipped with three Velcro front panels for fixing the necessary identification marks: a patch with a full name, a national patch and a central square patch with a title. This is a full-fledged replacement for field uniforms and therefore it contains all the necessary identification marks to identify the employee. This is really useful, although not very applicable in the case of civilian use of the jacket.

The jacket is fastened with a simple, non-moisture protective zipper - similar are used on jackets of the fourth windproof (L4) and sixth moisture protective (L6) layers. For additional protection against moisture and wind, the zipper is covered with a Velcro strap - this is convenient and practical, increases comfort and allows you to wear a jacket in case of failure of the front zipper.

Equipped with a jacket and two mortise pockets in the chest area. Mesh-lined pockets can be used for additional ventilation, and thanks to the design, access to them can be made even in the case of unloading and protective equipment dressed on top.

At the bottom, the jacket has a drawstring made of an elastic shock-cord, adjustable with two stops. This is a comprehensive solution, designed, firstly, to reduce blowing from the bottom of the jacket. In addition, it is necessary for more convenient access to user equipment located on the belt (waist or trouser belt with holster, unloading system such as war belt).

Sleeves of a straight cut, quite voluminous, adjustable by cuffs using Velcro. Unfortunately, the very quality of the Velcro, as well as its size, leaves much to be desired, especially in comparison with similar elements on the products of the previous generation of the multilayer kit. They are quite small, poorly fixed and quickly fail, which is why it is recommended to change them first.

There is reinforcement in the sleeves in the elbow area with the help of the second layer of a fairly strong material. This is one of the strongest jackets in terms of counteracting wear and tear, they are never worried about - an excellent example of the functional area of a product.

An important element in the design of the jacket are two pockets in the forearm. They, despite their not the largest size, are quite useful, and in addition, are equipped with panels for fixing a variety of patches. There is one more useful element of the functional on them - the IFF-square of recognition in the IR spectrum.

The collar of the jacket is ¾ high, quite comfortable. A hood is stored inside the collar, which is quite easy to get out and hide, without completely interfering at the same time - a rather useful functional element that helps a lot in the field and is not as interfering as an open collar.

The hood is quite voluminous, can be worn over helmets and voluminous winter hats. It is equipped with double adjustment: according to the oval of the face and volume / depth with the elastic shock-cord. A rather comfortable hood, which has only one drawback - it great covers the view, which is why many people prefer not to use it and keep it folded.

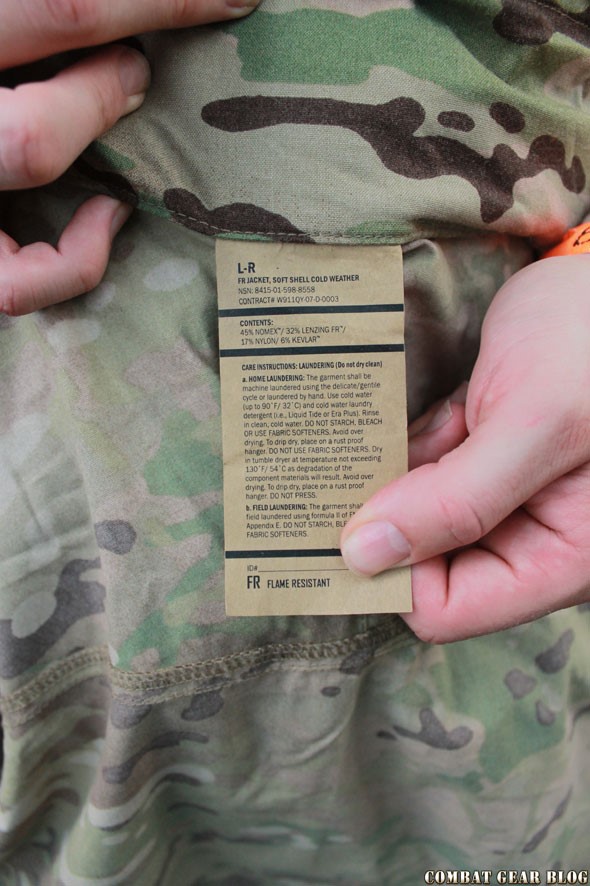

It is interesting that this layer is also made in fire-retardant design (with a small proportion of protective fibers in the composition of the material), in contrast to other layers and other generations. This is indicated on the jacket label, here you can also see the composition of the jacket, in the fireproof version it is 45% Nomex fibers 32% Leinzing material, 17% nylon and 6% Kevlar. The FR version has another feature - a slightly higher quality manufacturing.

The material itself for an unknowing person in operation is quite curious. It is lightweight, but provides good protection against wind and moisture, while not having in its design either an inner membrane film or a protective tape at the seams - like the membrane hard-walled moisture-proof kits. With high strength, he breathes quite well (although the jacket is equipped with additional ventilation holes in the armpits, covered with zippers) and is well suited to be worn as a base layer together with all other layers of the multilayer kit - in one or another combination. This is convenient and for its time it really was a breakthrough - in previous generations of multilayer kits, nothing like this simply existed. It feels thoughtful and quite a lot of work done, despite not the highest performance, traditional for contract products.

This jacket is quite convenient for both field and everyday urban use. It is more versatile and more variable to wear than the membrane sixth layer. Its use can be overshadowed only by the poor quality of the accessories used - mainly zippers and Velcro, which is easily fixable and is not a significant drawback.

In comparison with other products from softshell materials, this is one of the most budget options, while having due quality and functionality. It blends well even in color with the fourth and sixth layer, it is worn well with body layers and the seventh insulation layer, although due to the thickness of the material it has slightly worse compression properties. It can be safely recommended for anyone to buy, this is a really good option and excellent value for money.

The fifth layer of the ECWCS multilayer kit, in addition to the jacket, also includes pants made of the same material. Their use is quite ubiquitous and frequent - they are convenient and comfortable, but also quite warm. As soon as they began to be introduced into the army, among the soldiers immediately went the analogy between these trousers and old woolen models, with the only difference being that these trousers were lighter and had good rainfall and wind. They are more common than pants with a thick moisture-protective layer and, due to many features of the functional, deserve close attention. It is about them that will be discussed in this article.

An important feature of these trousers is the presence of full pockets. Full-fledged, not slits, as on the sixth layer. This is much better in the long term and is quite pleasant - pockets allow you to place various necessary property there and have it at hand. Pants are equipped with two mortise and two hip pockets - they will be discussed below.

The back of the trousers almost to the knee area is equipped with reinforcement from a double layer of fabric. A sufficiently extensive reinforcement (and not just in the buttocks area), together with a rather soft and thin main fabric, looks contrasting in comparison with solutions on similar trousers of other manufacturers, because it distinguishes these trousers from many classmates and makes them more reliable and adapted for field use . Although, it should be recognized that it is impossible to use them as full-fledged and permanent field trousers - it is rather temporary protective equipment, and if possible, field trousers should be used together with other layers (first and second).

The bottom of the trouser leg is equipped with zippers for easy dressing without removing shoes or on top of other layers of clothing. This is convenient, but the quality of the zippers is doubtful - they, like on a jacket of rather poor quality.

The lower part of the legs is rubberized with a rather wide elastic strap sewn from the inside. This is quite convenient, because it allows you to adjust the bottom of the legs in volume and eliminates blowing. The solution itself with an elastic band sewn from the inside is also not new, it was also found on earlier versions, for example, on the trousers of the MCCUU kit - there it was used in the design of hip cargo pockets to ensure greater reliability of the contents.

Curiously enough, the trousers were strengthened in the knee zone. It is made not with a simple piece of fabric, but with a somewhat articulated cut, complemented by scars. This provides freedom of movement, although it is a somewhat outdated (but more reliable) solution, different from that used on modern field pants, with pockets for installing integrated knee pads.

The thigh pockets of the trousers are quite voluminous, at the top they have a tightening (for better preservation of the contents of the pockets) using an elastic cord. They are fastened with a Velcro fastening valve, which is an operational, but not the most reliable solution - it would be nice to provide additional fixation with buttons or buttons.

In addition to saving mortise upper pockets, the trousers are also equipped with vertical zippers to access the pockets of other trousers - if you put these trousers on top of your field uniform.

These zippers do not reach the very top of the legs, in the belt area they are replaced by a Velcro fastener, which allows in theory to make additional adjustments in the belt area. However, in practice, this is a rather useless element of the functionality, which almost no one ever uses even to adjust the volume at the waist - this is quite a long time and inconvenient.

The pants are fastened with a zipper and are additionally fixed with the Velcro fastener and button. Frankly, the presence of "Velcro" in this clasp is considered by many to be unnecessary - one button already provides a fairly reliable fixation, and the "Velcro" is noise and additional complexity when opening. In addition, the very quality of the Velcro also leaves much to be desired. It is completely unclear why it is needed here, an absolutely unnecessary element of functionality.

The trousers are equipped with loops for a two-inch wide trouser belt (optimal for sharing with trouser belts 35 and 40 mm wide. The wider ones are not so comfortable to wear), but their presence seems to be a somewhat controversial element of functionality. Quite rarely, these trousers are worn with a belt, it is simply not needed here, largely due to the presence of a rubberized waist. Therefore, their presence is not so much a necessity.

A big plus is the presence of four attachment points (from a textile sling) for attaching suspenders. This is a variable version of wearing trousers, but quite useful - suspenders help keep the pants in one place and prevent them from slipping (although, in fairness, it should be noted that they rarely slip). Of course, there are no suspenders in the set - they are issued (or bought) separately, if necessary.

A fireproof version of trousers is provided here, which differs only in material - in a cut it is absolutely similar to the usual version. The material composition of the fireproof version of the trousers, according to the label: 45% Nomex, 32 linzing (fibers that provide fire resistance), 17% nylon and 6% Kevlar. Of course, no one tested these pants for fire resistance, but the presence of this function is an important feature.

In general, the pants are very successful. They are more thoughtful, easily adaptable to the user and, on the whole, are made much better than jackets. They hold moisture and wind well, are optimal for the cold season, are sewn with high quality. Claims arise only to fittings, however, its replacement is not very complicated and does not cause labor. This is an excellent soft shell option for cold weather, it can be safely recommended for both field and everyday urban use.